ISO Radaur road, Yamunanagar,

Haryana, 135001, India

Haryana, 135001, India

Email Us vjcsteel@yahoo.com

Contact +91-9138193907,

+91-9416141500

+91-9416141500

About Us

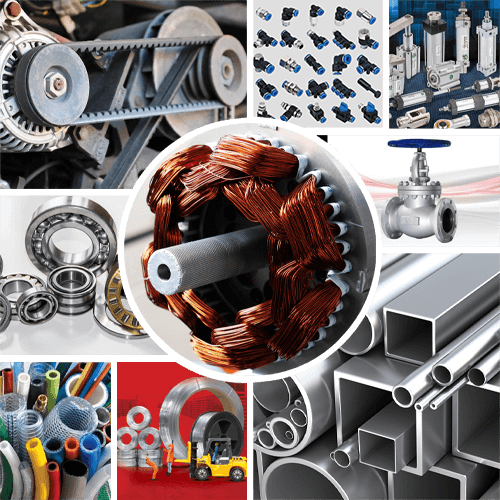

Since 1966, J.C. Engineers Pvt. Ltd. has made a name for itself in the list of top suppliers of in India. The supplier company is located in Yamunanagar, Haryana and is one of the leading sellers of listed products.

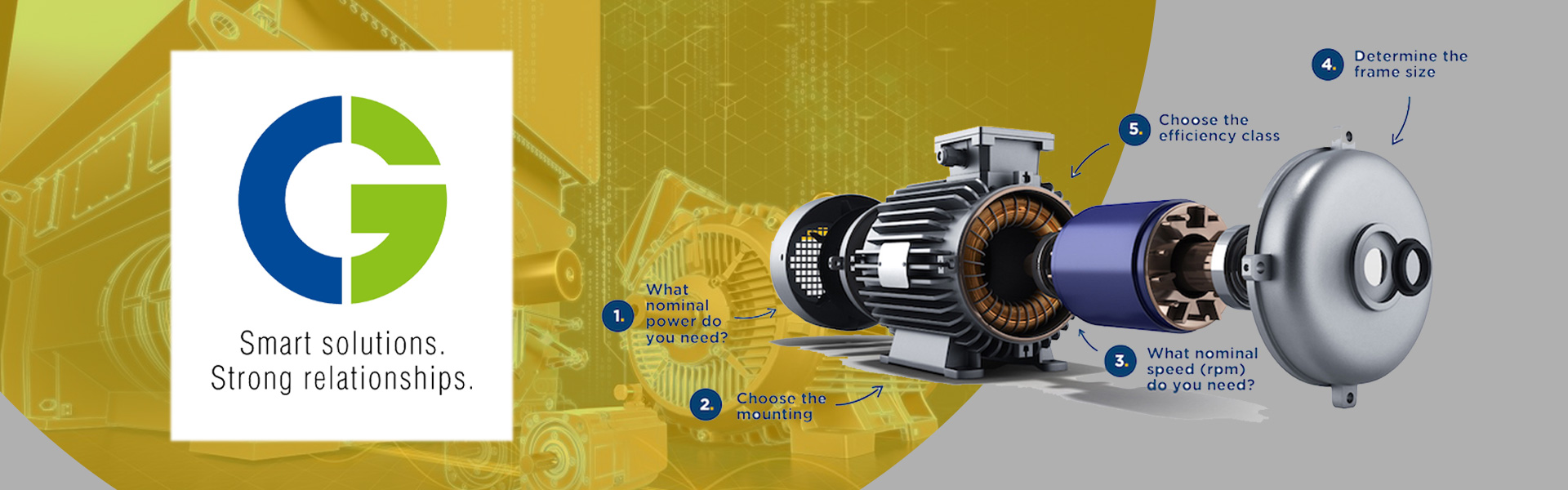

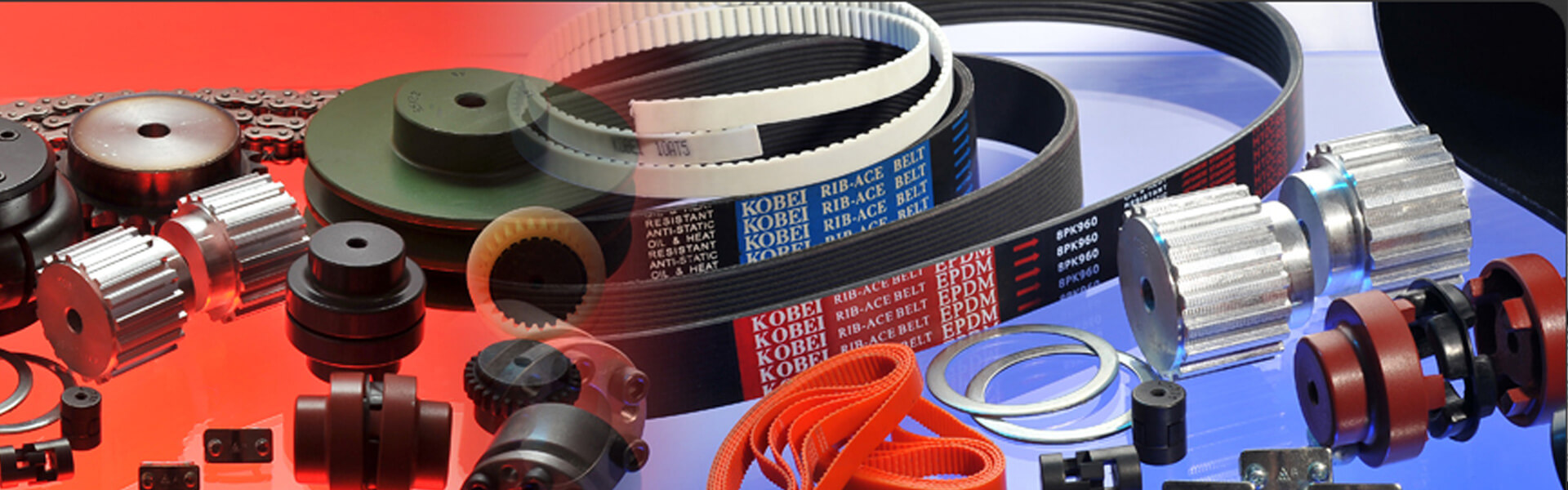

J.C. Engineers Pvt. Ltd. is an engineering conglomerate with an impressive and diverse portfolio of products, solutions and services for Power and Industrial equipment and solutions, addressing myriad needs.

J.C. Engineers, has always stood as a company with a rich repository of engineering capabilities, technological know how and enviable customer equity in the Indian Capital Goods sector. Its business presence across three GDP-enabling segments of Energy (power),